When you are looking into installing solar, research is one of the most important steps in ensuring you get what you need.

The amount of false information, misleading statistics and downright untruths can make this research quite challenging.

In this post, we hope to lay out what kinds of solar panels are available to domestic customers, how they work and where they are best suited for use.

It’s worth noting that almost all solar companies in the UK will be fitting Monocrystalline solar panels so don’t get too caught up in the types of panels. We will walk you through the differences and why Monocrystalline solar panels are the choice for most.

Polycrystalline solar panels

To simplify things a fair bit, photovoltaic cells are made up of tiny crystals of silicon melted together to catch the light protons and create electricity.

The manufacture of Polycrystalline solar panels means those crystals are fused together to create a cluster.

This is a much quicker and easier method of manufacturing than separating the crystals as the silicon is melted and simply poured into the cell moulds and allowed to set.

Simple manufacturing means cheaper production costs but, unfortunately, also means they aren’t as efficient as other panels.

The manufacturing process also means that these panels are more eco-friendly than their more efficient monocrystalline cousins, the silicon doesn’t need to be heated to such high temperatures so that lowers energy demands.

Polycrystalline panels are generally used in commercial settings such (ie solar farms) or large domestic installations.

You can identify these panels easily since they have a blue tinted colour.

Learn more about Polycrystalline Solar Panels.

Monocrystalline Solar Panels

Unlike Polycrystalline cells, the manufacture of monocrystalline cells requires each cell to consist of a single silicon crystal split into layers, so the process is much more wasteful, time-consuming and expensive.

However, it also means that monocrystalline panels are a lot more efficient as the energy can travel through the silicon much more quickly. Monocrystalline panels are generally found on domestic installations as they take up less space than their polycrystalline counterparts.

Learn more about Monocrystalline Solar Panels.

Passivated Emitter and Rear Cell (PERC) Solar Panels

PERC Panels are a relatively new invention and were first trialled in 1983 by Australian scientist Martin Green and his team at the University of New South Wales.

The problem Martin was trying to solve was making monocrystalline panels more efficient than they already were.

In a typical mono cell, many of the photons (or light) can fly straight through the silicon without hitting any atoms – which means less efficiency, as much of the usable light is wasted.

Dr Green and his team tried to increase the number of photons making contact with the silicon crystal by adding materials to reflect, channel and bounce them around inside the cell.

Using 2 ‘reflective’ layers at the back of the cell allows the protons to be bounced back into the silicon thus increasing the efficiency of the panel to 23% – 24%.

It took decades to make this technology affordable for the market, which is why we are only just seeing PERC Panels being used in commercial settings.

Learn more about PERC solar panels.

Thin-film solar panels

We mention these just to ensure you know what is available on the market but these second generation panels wouldn’t be suitable for a domestic installation.

Instead of using silicon crystals to generate electricity, thin layers of photovoltaic material are placed on top of each other. These materials are either amorphous silicon, cadmium telluride, copper indium gallium selenide and organic PV cells.

This kind of panel generally works at about 5% lower efficiency than other panels and has a shorter lifespan but is much more flexible and can be used in places where solid panels can’t.

They can frequently be found on the roofs of caravans, motorhomes and narrow boats as a low-weight and air resistance alternative.

Learn more about Thin Film solar panels.

Solar tiles

Much like thin-film solar panels, the solar tile is not yet widely available in the UK.

They can be ordered through Tesla and there are 3 other companies in Britain offering to supply or install.

As the name suggests, these are smaller solar panels that are constructed to double up as roof tiles.

They can be used on most pitched roofs, and have an efficiency rating of around 13% as they are less able to dissipate heat compared to mounted panels, which can reduce their voltage.

Obviously that is much lower than monocrystalline panels, but they are installed across the entire roof, so there will be plenty of power being generated. At the moment solar tiles have to be installed on pitch-perfect roofs, they can’t be added to existing roofs and they are very expensive.

That cost could be off-set with the savings you would make on normal tiles if you are replacing your roof or starting from scratch.

Which solar panels are best for domestic installations?

Monocrystalline panels are the best for domestic installation. They are the most efficient for the price. While poly panels are rated at about 18% – 22% efficiency, mono panels are racking up a whopping 24%.

If you are installing split Monocrystalline cell panels, ones with a cell count of 108, you will not only be getting more power, you’ll be getting more efficiency per panel. More efficiency means less panels too, so that makes monocrystalline systems the best for rooftop insulation.

Which solar panels are best for commercial installations?

While the monocrystalline panels are more efficient, they are also more expensive.

So, there will come a point where having less efficient panels will become a cost effective solution and that usually depends on how much room you have.

Most solar farms, the ones you can see from the road as you pass, are constructed using polycrystalline panels due to their affordability. Some commercial installations may also use thin-film panels if the area where they are being mounted is awkward or curved.

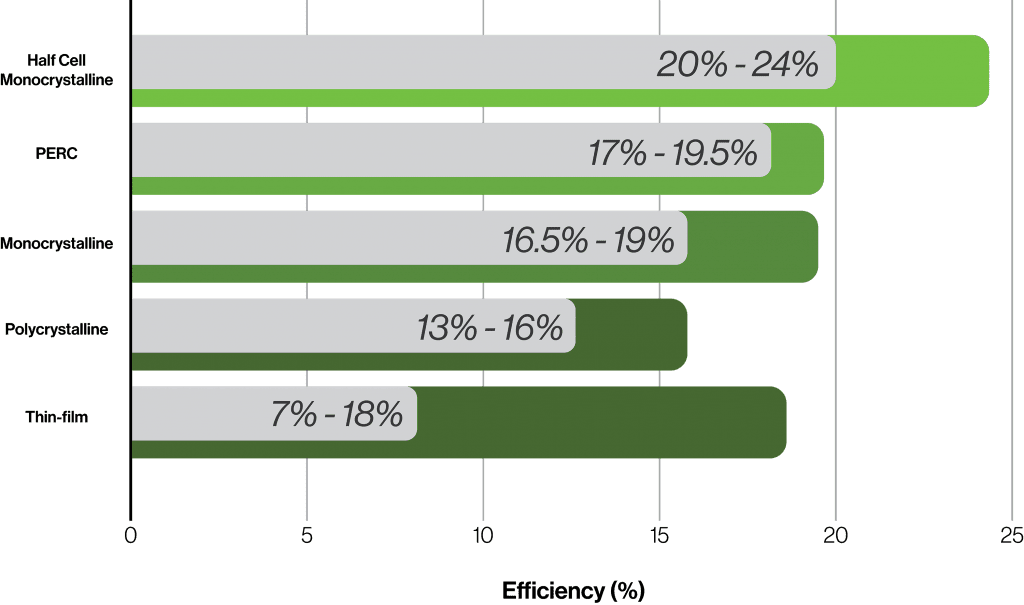

Which panels are the most efficient?

We have covered this a fair bit so far but we will just sum up the efficiencies of the different panels, with the split cell mono crystalline coming in top and the poor old thin-film foundering at the bottom.

Half Cell Monocrystalline – 20% – 24%

PERC – 17% to 19.5%

Monocrystalline – 16.5% to 19%

Polycrystalline – 13% and 16%

Thin-film – 7% and up to 18%

Best Panels for high and low temperature

Electricity moves more freely at lower temperatures. This means, as the heat increases inside the photovoltaic cell it becomes less efficient.

Polycrystalline solar panels have a higher temperature coefficient than monocrystalline panels. In layman’s terms that means the heat affects the efficiency more than it would in a monocrystalline panel.

So, once again, the mono panels perform better in extreme conditions, which is a moot point here in blight as even polycrystalline panels have an acceptable maximum temperature of 85 °C and a minimum temperature of -40 °C.

But, as the UK rarely sees temperatures this extreme, most solar panels function very well in our green and pleasant land.

What are the most durable solar panels?

This is another win for monocrystalline panels. The fact they use individual silicon crystals means they can stand more heat, cold and more knocks.

That said, poly panels are pretty indestructible too. While there is more chance of damaging a silicon crystal as they are all fused together, you’d have to do some pretty serious damage to a panel to affect its efficiency.

Most solar panels will still be working at 80% of their full power even after 25 years.

Learn more about solar panel lifespan.

Tiny amounts of damage to solar panels decrease efficiency through degradation.

Basically, anything that increases the amount of light energy that will be absorbed before it reaches the semiconductor will reduce efficiency.

Usually, this will be: tiny scratches, water damage, stains, etc.

| Type Of Panel | Power output | Cost | Efficiency | Flexibility |

|---|---|---|---|---|

| Polycrystalline | 260 Watts | Average £250 | 13% – 16% | None |

| Monocrystalline | 360 Watts | Average £250 – £300 | 20% | None |

| Half Cell Monocrystalline | 405 Watts | Average £100 – £200 | 24% | None |

| Thin Film | 200 Watts | £250 | 7% – 18% | Some |

Fire, hail and hurricane rating

Once again the ratings for most solar panels tend to be set to international standards.

Here in the UK we have no need to worry about enormous hailstones or 80 mph winds, so we are just interested in fire ratings.

Most panels, whether poly or monocrystalline, have a Class C Fire Rating which states the item is effective against light fire test exposure and the flame spread should not go beyond 4 metres. This is a standard that applies to most building materials including plywood, fibre-board, and hardboard.

Panels used on solar farms and other large, outdoor settings would have a lower Class B fire rating.

What else do you need to know about solar panels?

As always, the devil is the detail and it’s not just the material the panel is made of that is important – how it’s made will also affect its performance.

Solar panel cell count

Cell counts only really apply to monocrystalline and polycrystalline panels as they are the ones that use cell arrays.

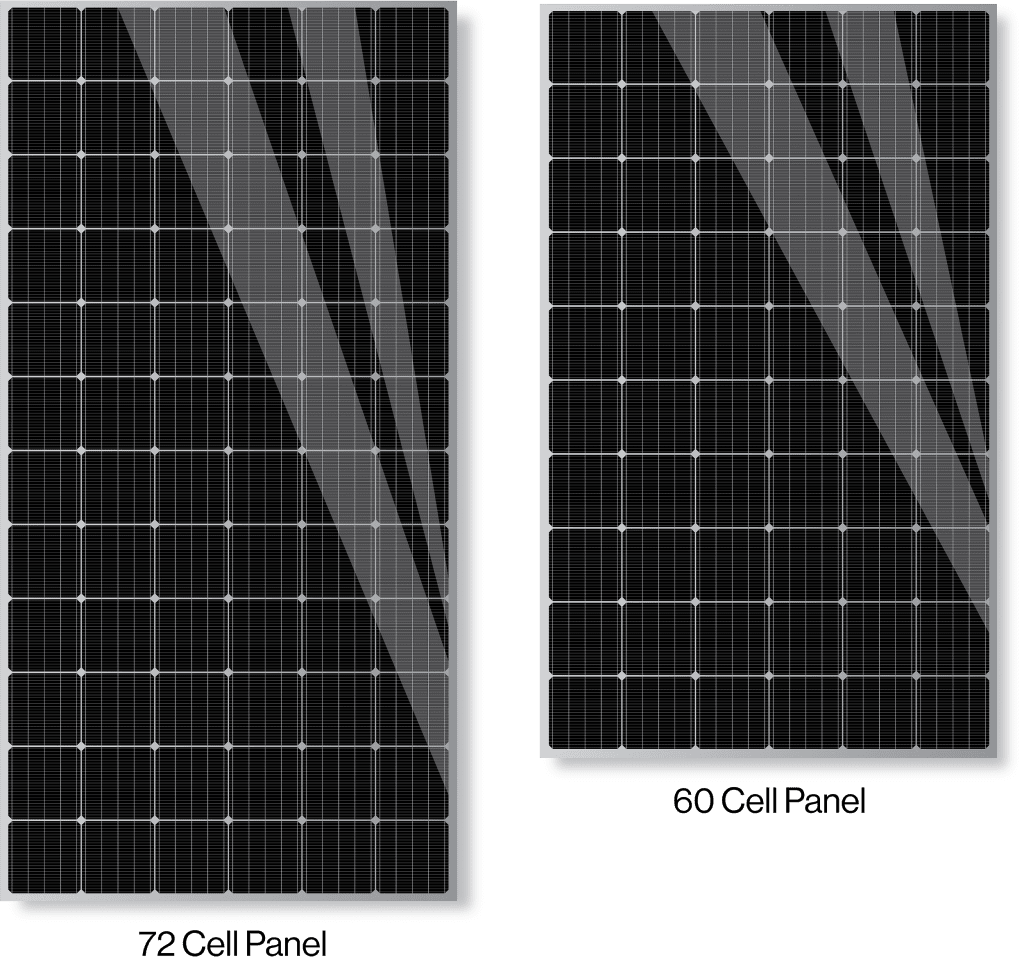

60 and 72 Cell Panels

These two sizes are the industry standard at the moment, coming in 10 cells by 6 or 12 cells by 6.

The larger size obviously produces the most electricity but both are equally efficient. Going for a larger panel means you will need fewer pieces for your installation but will need quite a big roof, whereas the 6 x 10 will fit nicely on most domestic roofs and you can add more panels.

108 Cell Panels

These are the GOAT of domestic solar panels coming in.

The technology is slightly different as the arrays are made up of 54 cells that have been split in half. While this seems a little unscientific, it actually means there is less material for the charged electrons to travel through, lowering the resistance of the cell and increasing its efficiency.

Using this method, smaller panels can be used to create the same amount of energy.

Other Cell Count Panels

- 32 Cells – Used for small battery charging

- 36 Cells – Used for larger battery charging such as those for cars and vans

- 48 Cells – Used for utilities such as trafficlights

- 108 Cells – a split cell 54 count panel, quite expensive